Powered by EU-funding, a consortium consisting of the world’s leading marine experts and engineers are working together to create an innovative new fouling protection system for commercial seagoing vessels, and to accelerate its entry to market. This project is called eSHaRk (Eco-friendly Ship Hull film system with fouling release and fuel saving properties).

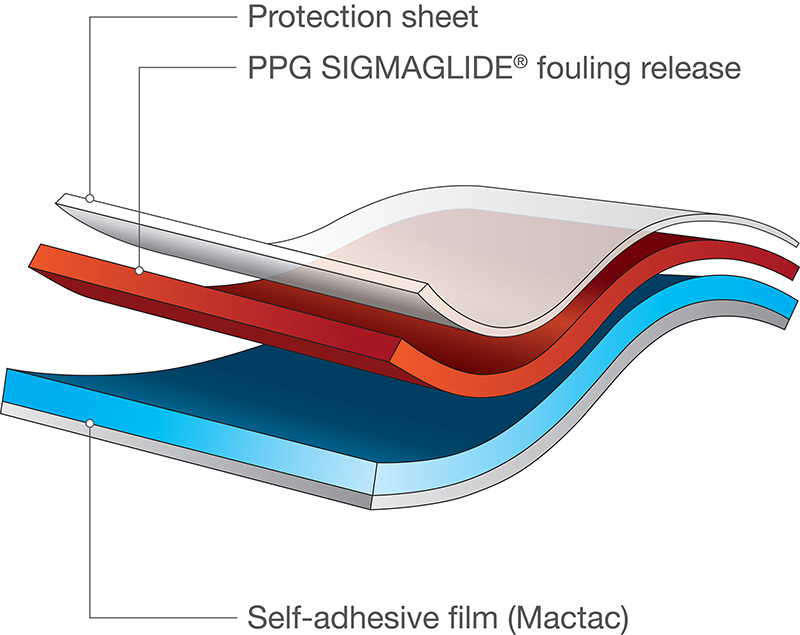

The EU funded eSHaRk project (#691495) aims to bring a greener and more efficient anti-fouling solution to the market, consisting of:

This innovative new technology not only maintains current fouling protection standards but is superior to existing solutions in terms of eco-friendliness, ease of application, durability and drag-reduction, all of which will lead to fuel savings and a reduction in greenhouse gas (GHG) emissions.

Fouling, defined as the settlement and growth of marine organisms on submerged structures such as ship hulls, is a constant challenge for the shipping industry. Fouling results in higher hydrodynamic drag of vessels, which in turn leads to higher fuel usage and emissions of greenhouse gases (GHG).

eSHaRk technology applies state-of-the art silicone fouling release technology onto a self-adhesive film specially designed for underwater exposure. This results in an environmentally friendly and easy to apply fouling release solution that exceeds the performance of fouling release technology currently available on the market.

The eSHaRk solution is expected to have superior drag reduction properties compared with existing paint-based anti-fouling and fouling release technologies. A 10% drag reduction is expected, compared to the maximum of 5% offered by traditional products.

The adoption of a film-based structure opens up new possibilities for optimizing the morphology of the products’ surface, leading to enhanced fouling protection and superior drag reduction properties. This can contribute towards greater fuel efficiency of large commercial vessels and hence reduce their emissions of greenhouse gases (GHG).

Furthermore, the application of the film-based product on ship hulls can be automated, and thus be made more efficient, easier, safer and cleaner than with current paint-based products.

23rd May 2016

Pittsburgh, May 23, 2016 – PPG's (NYSE: PPG) protective and marine business has received EU Funding for an exciting new project which aims to produce an innovative fouling protection system for commercial vessels.